That’s where the edge banding machine comes in. It’s not just about making things look nice; it’s also about protecting furniture from potential damage, especially for furniture made from materials like plywood, particle board, and medium-density fiberboard (MDF). While these materials are good alternatives to solid wood, they need extra protection. Edge banding acts as a shield,keeping furniture both good-looking and sturdy in the face of challenges.

Different techniques to apply edge banding

Edge banding plays a pivotal role in enhancing the aesthetic appeal and durability of furniture. Exploring various techniques is essential for achieving different results that cater to the specific requirements of furniture manufacturing.

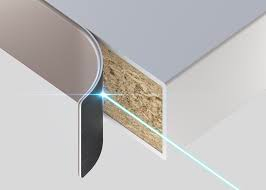

Laser Edging

One cutting-edge method for applying edge banding is through laser technology. In this advanced process, an edge banding machine utilizes precise laser beams to seamlessly fuse the banding material with the furniture edges. The result is a flawless finish, devoid of visible seams, imparting a sleek and modern appearance to the furniture. Laser edging showcases the forefront of technology in achieving high-quality edge banding outcomes.

Hot air and Hot glue

A time-tested and effective technique involves the application of hot air and hot glue. This traditional method utilizes an edge banding machine to apply heat, activating the adhesive properties of the banding material. The outcome is a robust bond between the material and the furniture edges, not only enhancing the visual appeal but also reinforcing the structural integrity of the furniture. This method combines the reliability of traditional craftsmanship with modern machinery.

Iron-On Application

Similar to traditional craftsmanship, the iron-on application method involves the use of an edge banding machine to apply heat, activating a pre-applied adhesive on the banding material. This simplicity and speed make it a preferred choice for efficient and high-quality production. The iron-on application ensures a quick and secure bond, showcasing the versatility of edge banding techniques.

Pressure-Sensitive Adhesive (PSA)

For those prioritizing efficiency without compromising precision, the Pressure-Sensitive Adhesive (PSA) method is a go-to choice. Equipped with a self-adhesive backing, the edge banding machine simplifies the application process, allowing for accurate and swift edge banding. This technique is particularly suitable for projects where time is of the essence without compromising the precision required for impeccable edge banding results.

Choosing the appropriate edge banding technique is an art that involves aligning the chosen method with the specific needs of the furniture being produced. Each technique, whether embracing modernity with laser edging or relying on traditional methods with hot air and hot glue, emphasizes the meticulous nature of this crucial process in crafting top-notch furniture. The versatility of edge banding techniques is paramount in achieving the desired balance between aesthetics and functionality.

Exploring Types of Edge Banding

In the intricate world of furniture manufacturing, edge banding plays a crucial role, and the utilization of special machines significantly contributes to achieving flawless results. Let’s delve deeper into some of these cutting-edge machines and understand how they revolutionize the edge banding process.

Laser Edge Banding Systems

At the forefront of modern technology are Laser Edge Banding Systems. These machines employ advanced techniques to achieve a seamless finish without relying on traditional glues. Instead, a special polymer layer is utilized to join the edge banding with the board. This not only ensures a flawless appearance but also highlights the adaptability of modern edge banding techniques. The synergy of various technologies such as hot air, laser, plasma, and near-infrared showcases the versatility and precision that define contemporary edge banding.

T-Molding Machines

T-Molding Machines are specifically designed for the application of T-Molding, a method renowned for its durability and flexibility. These machines intricately insert the T-shaped extrusion into precisely cut slots on the edge of a panel. The result is not only a perfect fit but also a robust shield against impacts, adding both functionality and a polished aesthetic to the furniture. T-Molding Machines exemplify the marriage of precision and strength in edge banding.

In this amalgamation of materials and techniques, innovation and precision emerge as key components. The edge banding machines act as conductors orchestrating a harmonious blend of style and strength in every piece of furniture. The marriage of high-tech tools and timeless craftsmanship ensures that each item undergoing the edge banding process becomes a testament to perfection.

As the furniture industry strides forward, we anticipate continuous advancements. The relentless pursuit of innovation in materials, techniques, and machinery will continually redefine the possibilities within edge banding. This ongoing exploration not only guarantees that every piece created meets elevated quality standards but also pushes the boundaries of creativity and functionality, reinforcing the importance of edge banding in the evolving landscape of furniture manufacturing.

The future of edge banding

As we embark on a journey through the realm of edge banding and the pivotal role played by the edge banding machine, it becomes evident that this collaborative partnership is poised for continuous improvement. The future of furniture production will be shaped by ongoing innovations in materials, application techniques, and machinery, setting the stage for each piece to not only meet but exceed the expectations of professionals and enthusiasts within the industry.

The evolution of edge banding is closely tied to advancements in materials. Future iterations are likely to witness the introduction of novel materials that offer enhanced durability, flexibility, and aesthetic possibilities. This could lead to a broader range of choices for furniture designers and manufacturers, allowing them to push the boundaries of creativity and functionality.

Application techniques are another frontier where the future of edge banding holds promise. Continued research and development will likely result in even more efficient and precise methods of applying edge banding. The industry might see the integration of artificial intelligence and automation, further streamlining the process and ensuring consistent, high-quality outcomes. These advancements in techniques will undoubtedly contribute to the overall efficiency and productivity of furniture production.

Furthermore, the future of edge banding machinery is anticipated to bring forth innovations that cater to the evolving needs of the industry. Enhanced precision, faster processing speeds, and increased versatility are aspects that manufacturers may prioritize. The integration of smart technologies within edge banding machines could facilitate real-time monitoring and adjustments, ensuring optimal performance throughout the production process.

Conclusion

The intricate connection between edge banding and the edge banding machine signifies a steadfast commitment to excellence in furniture craftsmanship. The trajectory of the industry indicates that as it advances, the synergy of technical expertise and artistic vision will lead to a bright future. Furniture, in the evolving landscape, transcends mere functionality; it embodies a seamless fusion of design, utility, and enduring excellence. At the core of this transformative journey stands the edge banding machine, diligently ensuring that every piece is meticulously crafted with precision and style.

As we look ahead, the continued refinement of edge banding techniques and machinery will undoubtedly play a pivotal role in shaping the narrative of furniture production. The future promises not only a continuation of high standards but also a paradigm shift towards unparalleled innovation in the dynamic world of edge banding.

To know more about Edge Banding applications and benefits, Click here

Exemplary Edge Banding Solution for Decorative Laminates: LamEdge Pro

Introducing Lamedge Pro, Explore over 5,00,000 matching results with Youva!

LameEdge Pro revolutionizes the user experience by offering a mobile-friendly and efficient platform Best Solution for Top laminate brands in india, a key element in empowering users. Through a user-friendly interface, individuals can effortlessly explore a diverse range of PVC edge banding tapes with just a few clicks. This accessibility is particularly advantageous in dynamic industries like manufacturing and design, where the ability to make swift and informed decisions is paramount.

Functioning as a personalized guide for Merino Laminate customers, LameEdge Pro streamlines the process of finding the ideal PVC edge banding tape to complement Merino’s extensive array of laminate products. The application’s database is meticulously crafted to align with Merino’s color schemes, patterns, and textures, ensuring a seamless transition between edge banding and various Merino laminate types. This tailored approach not only facilitates a cohesive aesthetic in the final product but also optimizes time efficiency in the decision-making process.

To know more about Edge Banding machines, Click here